spoonset, 2016

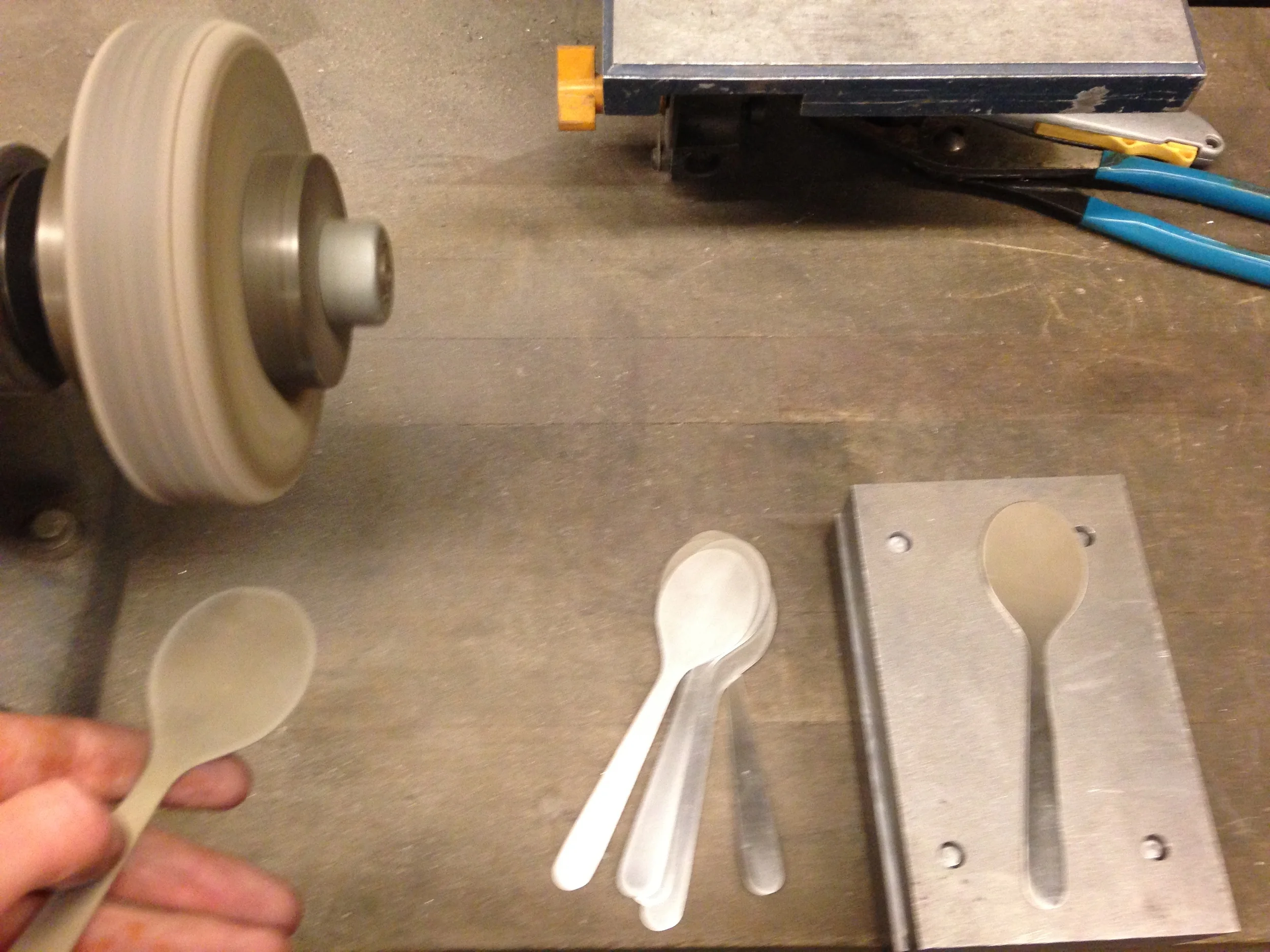

twenty five stainless steel dessert spoons formed with a CNC machined die set

materials and processes: mild steel, CNC machining, 304 stainless steel sheet, forming with hydraulic hand press

created for a design

and manufacturing course at stanford, these spoons and dies went through a complete design-to-

manufacturing

process.

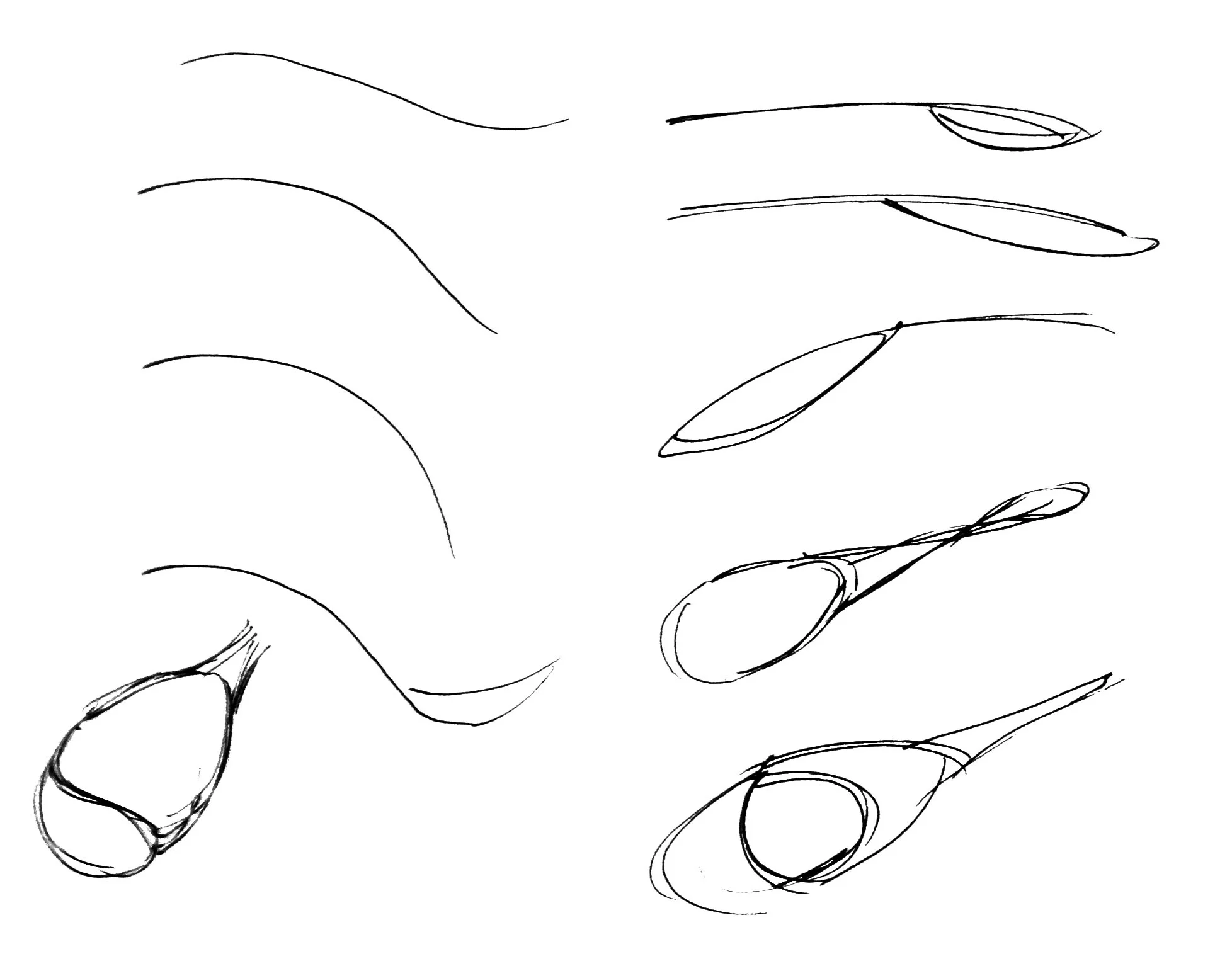

concept sketches and clay prototypes

machined prototype for proof of concept, handle prototyped using cardboard

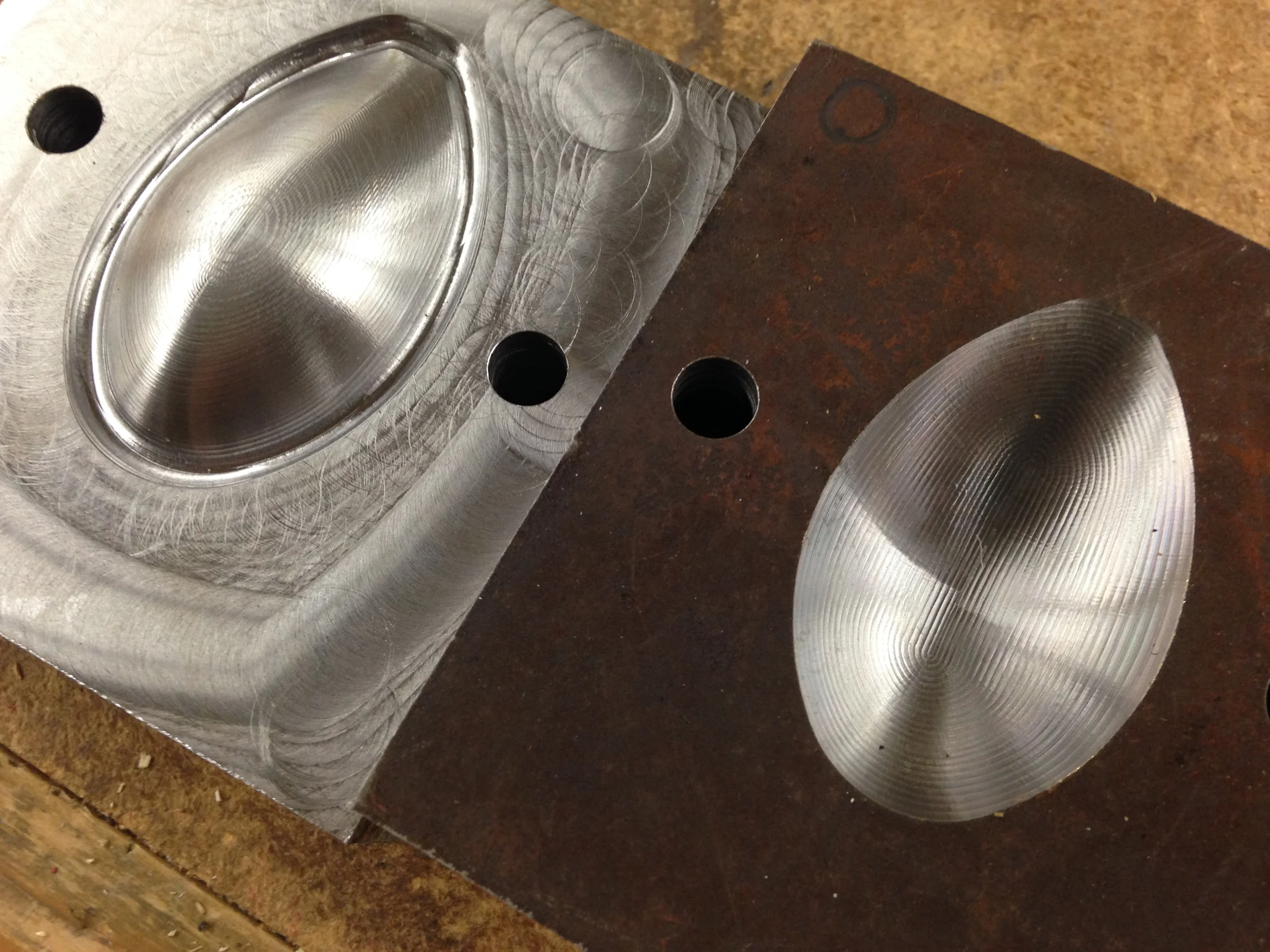

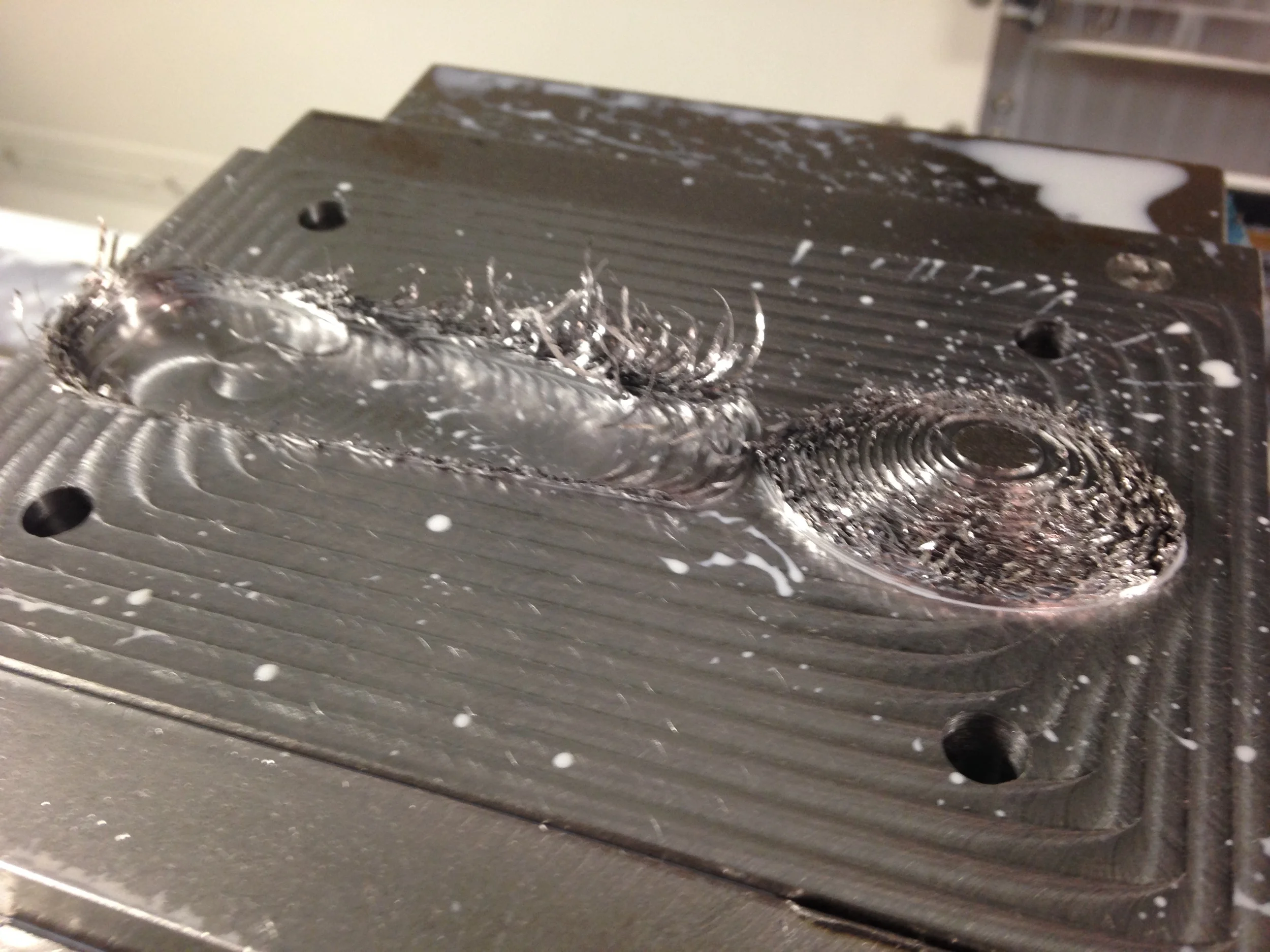

final spoon shape and forming dies modeled in solidworks using surfacing and mold tools, then geometry converted to CNC machine code

i machined the dies on two different Haas VF1 CNC milling machines in the stanford product realization lab.

the final machining time was 2-3 hours per die, but required many more hours of planning, debugging, and test cuts.

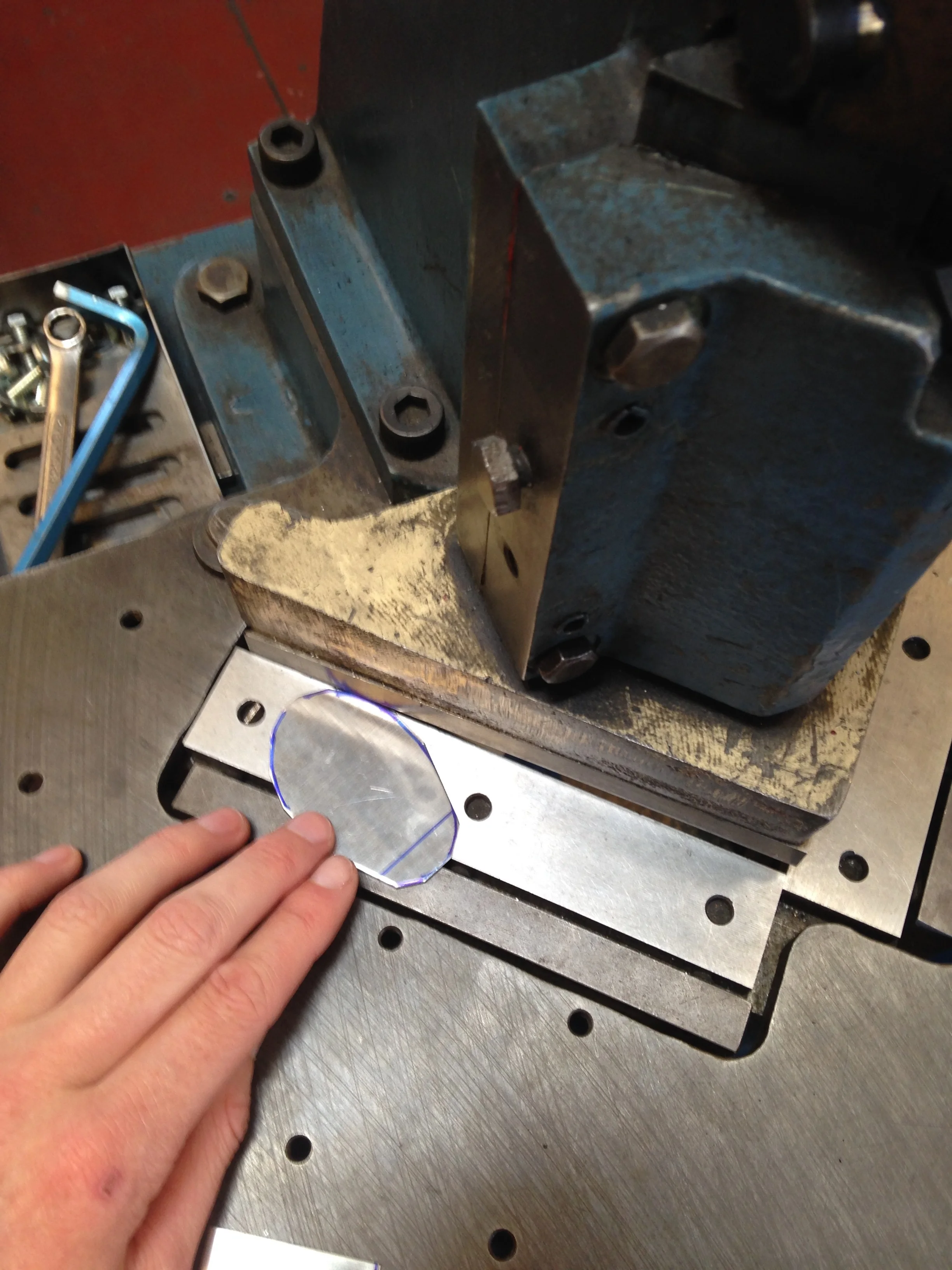

after creating several prototype spoon blanks, i sent the finalized spoon blank geometry out for water jet cutting.

i then used a hand-operated hydraulic press to form the spoon blanks into the final spoon shape.

the 25 spoons were given to family members and friends, with custom handle designs for each person.

lessons learned!

include an alignment feature for the spoon blanks;

aggressive feeds, speeds, and depth of cut lead to dull tools, so consider the tradeoffs;

oh, and when you accomplish something big, celebrate!!

many thanks to my classmates, loftees, mentors, shop TA's and the teaching team

for supporting me in this design and manufacturing adventure!