rwanda hydropower project, 2010-2011

small-scale hydroelectric turbine that charges batteries for residents of banda, rwanda

materials and processes: aluminum, steel, pvc piping, valves and connectors, bearings, 3D printing, plastic casting, sand casting, post-machining, welding, engineering drawings

banda is a remote village in the southwest corner of rwanda. in the summer of 2011, dartmouth humanitarian engineering (DHE) installed a hydroelectric turbine in the village to replace a previously broken turbine. the turbine provides residents with electricity to charge car batteries, which then power phone chargers, DC lightbulbs, and electric razors.

my involvement in this project was twofold. first, my engineering capstone team project was sponsored by DHE, who commissioned us to optimize the geometry of the turbine and prototype a new design from september 2010 to march 2011. when the course was finished, i then joined the DHE team as the mechanical lead to fabricate the turbine and implement the installation in rwanda during the summer of 2011.

context: turbine explained

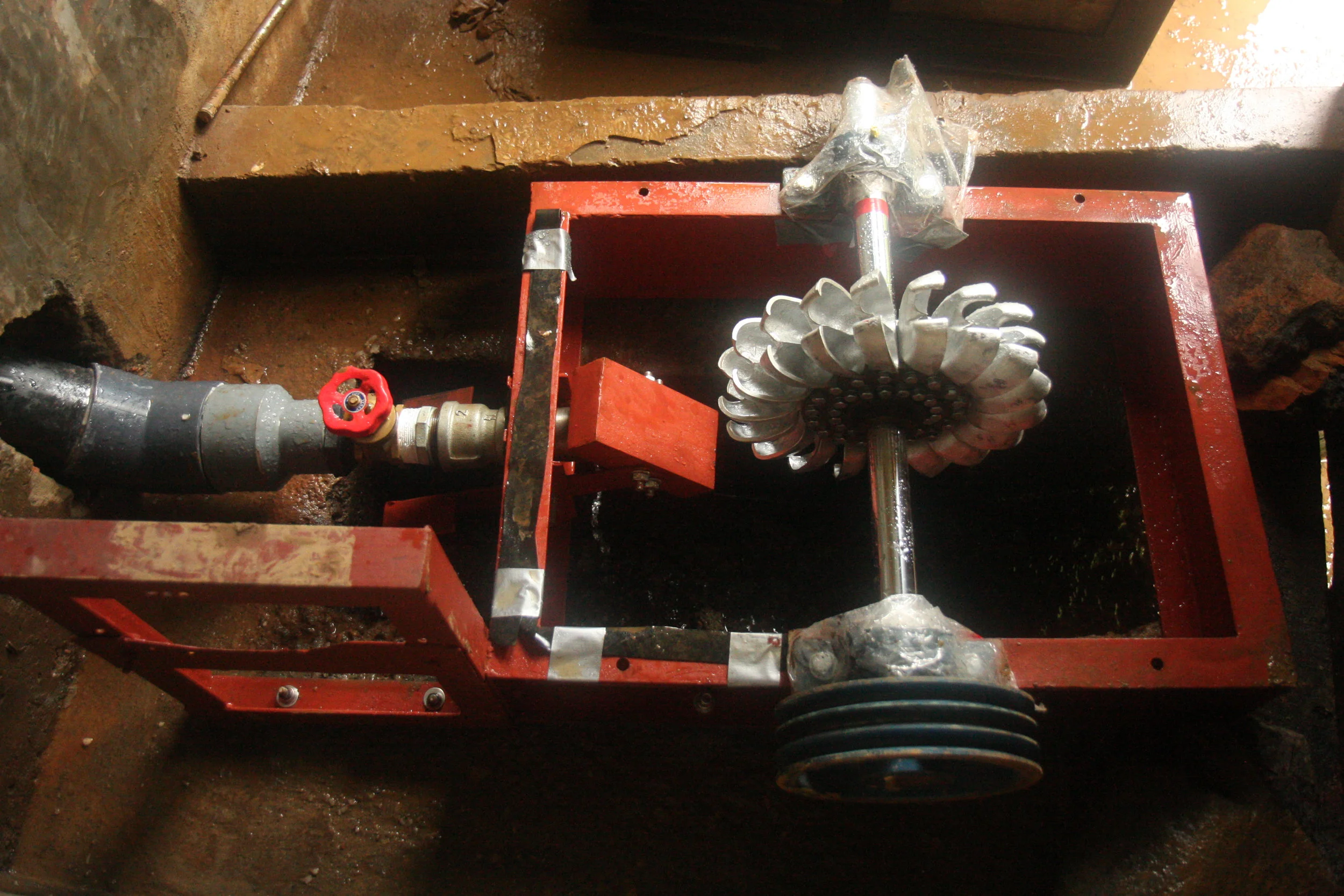

the turbine installed in banda is a pelton turbine, which is a type of impulse turbine.

an impulse turbine has buckets with a center blade that reverse the direction of water coming out of a nozzle. this reversal of direction creates a change in the momentum of the water, which in turn generates a force on the turbine bucket creating rotational energy of the runner. the rotational energy can then be used to do work. in this case, the shaft is linked via a pulley to a truck alternator that charges lead acid car batteries.

Part i: capstone team project

specific contributions to the capstone project included creating SolidWorks CAD models of the runners and buckets,

3D printing plastic bucket models, using silicone to create a mold for casting more plastic buckets,

and designing a closed-loop indoor test set-up and high-speed video analysis procedure.

turbine fabrication:

3D printed buckets are used to create a silicone mold for casting plastic buckets

turbine testing and optimization:

water circulates from the bucket below through a .75hp centrifugal pump to the nozzle.

a window on the side of the turbine housing provides access for high-speed video analysis of the water flow from the nozzle to the turbine buckets.

part ii: rwanda implementation

specific contributions to the rwanda implementation included taking on the role of mechanical lead for the project, collaborating with a local vendor in NH to design and sand cast the turbine buckets, post-machining the buckets after casting, creating a schedule for implementation in rwanda, directing in-country fabrication of turbine housing, and leading the installation, testing, and troubleshooting of the turbine in the village of banda, rwanda.

preparing for rwanda:

bucket CAD modeling and design optimization;

sand casting and post-machining, in collaboration with local vendors and DHE teammates

rwanda implementation:

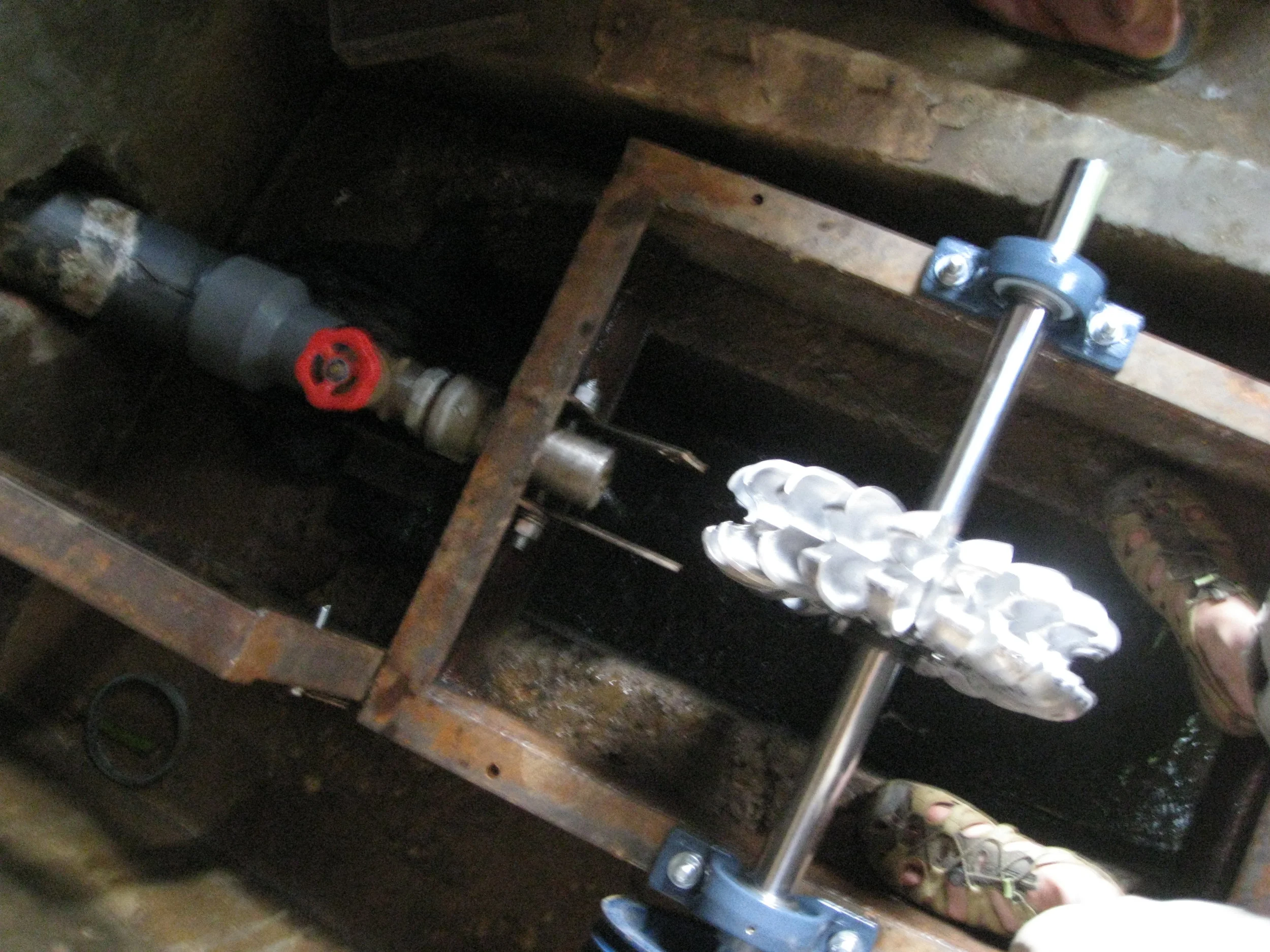

the DHE team worked with students from Kigali Institute of Science and Technology (KIST) and ETO Muhima mechanic school to source materials and fabricate the turbine case for the first two weeks of the trip

rwanda implementation:

for the remaining month and a half of the trip, the team in banda village worked on

removing the broken turbine, and installing, testing, and troubleshooting the new turbine

rwanda implementation:

the completed system now provides electricity to charge batteries for the people of banda, rwanda

many thanks to my teammates and advisors along the way,

and to my friends in banda who welcomed our team and made this project possible!

for more information on this project, see Dartmouth's Humanitarian Engineering Website, and additional links below:

DHE Website: http://www.dhedartmouth.org/projects/hydropower/

Google Photos shared album: https://goo.gl/photos/qQFqTD3rSZPVNjQr8

Seacoast Online news article: http://www.seacoastonline.com/article/20110930/NEWS/109300360

Dartmouth Engineer Magazine article: http://engineering.dartmouth.edu/magazine/humanitarian-engineering-students-upgrade-hydropower-system-in-rwanda

photo credit: emily porter and ted sumers