recycling robot, 2020-2022

an AI-enabled robot that sorts recyclables in waste facilities

materials and processes: steel tubing, welding, aluminum, sheet metal fabrication, powder coating, machining, 3D printing

this robot is glacier’s first sales product to be installed in a recycling facility. using a proprietary computer vision system, this robot can identify and sort six different commodities over two conveyor lines - a feat that no other robot in the industry can do.

as the first hire at glacier, i served as the lead mechanical engineer and project engineer for this robot and for several prior pilots and prototypes, enabling seed funding and exit from stealth.

key contributions to the company and robot development included:

leading the design and development process and growth strategy

designing the structural support assembly, robot enclosure, and critical end-of-arm mechanism

collaborating with other glacier engineers to develop and test pneumatic, actuation, and electrical systems

documenting all aspects of design using CAD models and drawings, calculation spreadsheets, and design journals

partnering with our first customer to define requirements, maintain the schedule, and ensure successful installation

glacier is an early-stage startup, so i am unable to share information that is not publicly available.

everything shared below is purely representational of the type of work i did and does not reflect any proprietary or confidential info.

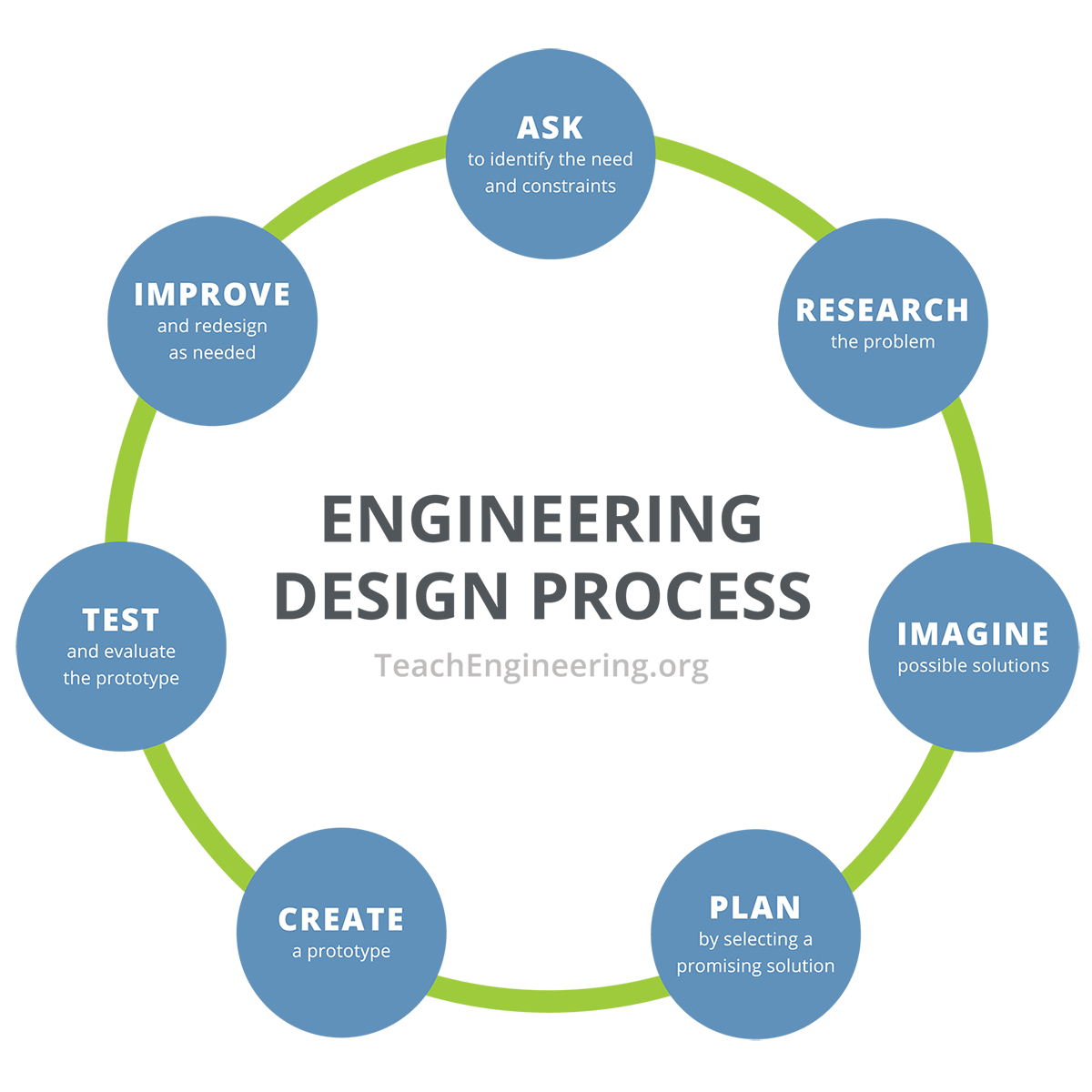

leading the design and development process

as the mechanical lead, i incorporated design and development best practices into my work and set process standards for the team.

some examples of typical processes are shown below.

designing and documenting assemblies, parts, and mechanisms

the detailed engineering work i completed included brainstorms, mind maps, detailed conceptual sketches, prototyping, top-down CAD modeling, hand calculations and parametric sizing spreadsheets, basic structural analysis, subsystem testing, design-for-manufacturing conversations with vendors, design release packages, and facility drawings.

in addition to holding primary responsibility for the robot structural frame, enclosure, and end-of-arm mechanism, i also coached, advised, and collaborated with my mechanical and software teammates to ensure high quality design of electrical, pneumatic, and actuation components and systems.

During COVID, I built a sheet metal bending brake at home, for prototyping sheet metal parts.

Partnering with customers

to ensure an on-time and worry-free installation of our robot, i worked with our customer team to set expectations, clearly define requirements, and track progress.

during our installation, glacier’s team worked tirelessly with our customer team to meet their uptime needs on day 1.

glacier’s install team is shown below (co-founders plus mechanical team)