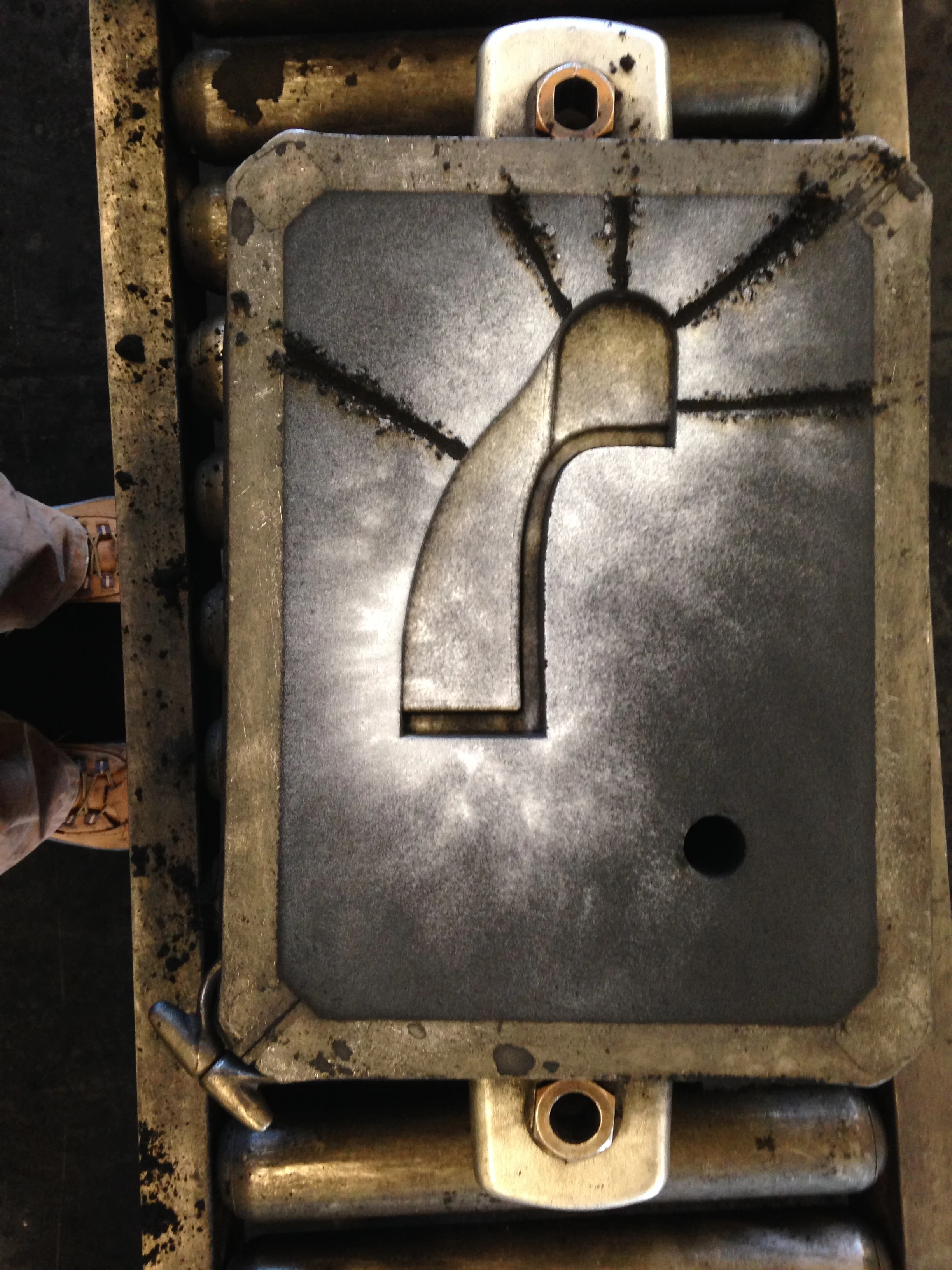

impression, 2015

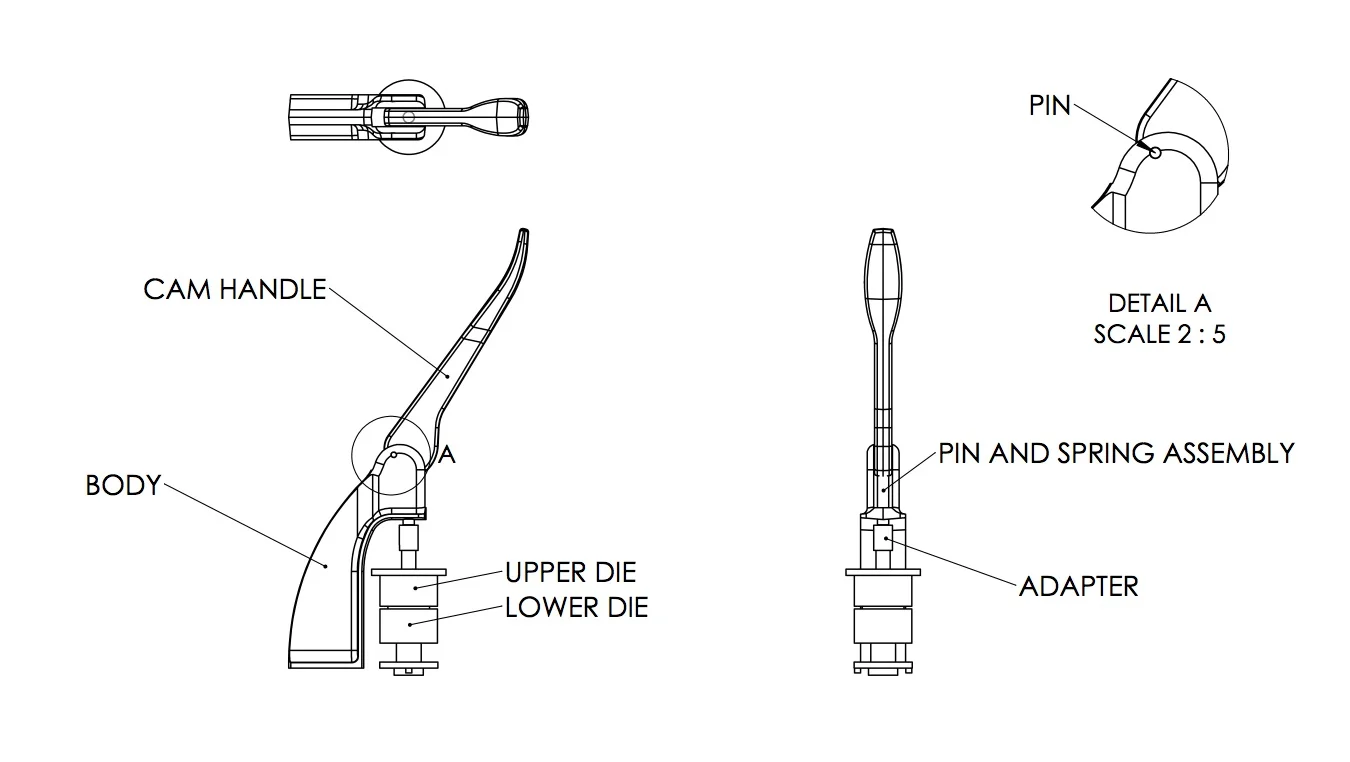

a hand press that makes custom pin-back buttons

materials and processes: walnut, woodworking, bronze, sand casting, brass, machining, purchased stainless steel forming dies and steel hardware

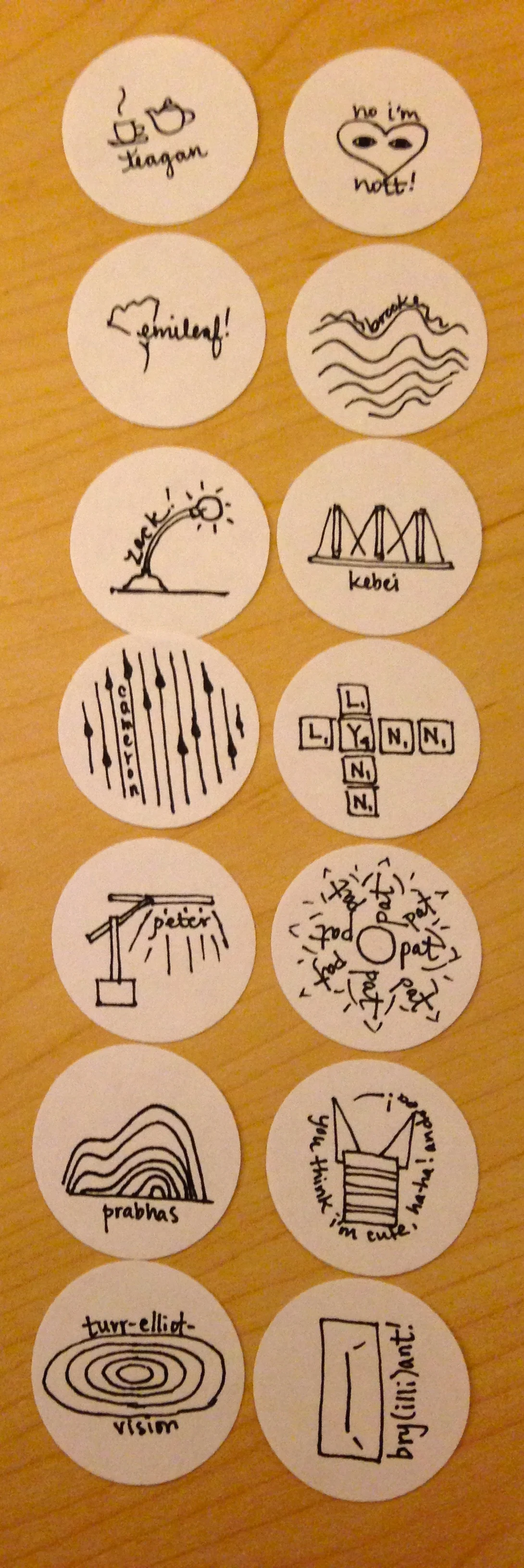

this homemade button press

was inspired by two of my roommates who made a leaf button for me earlier

in the year. the purpose of impression is to spread joy by enabling people to craft

custom buttons and share with others.

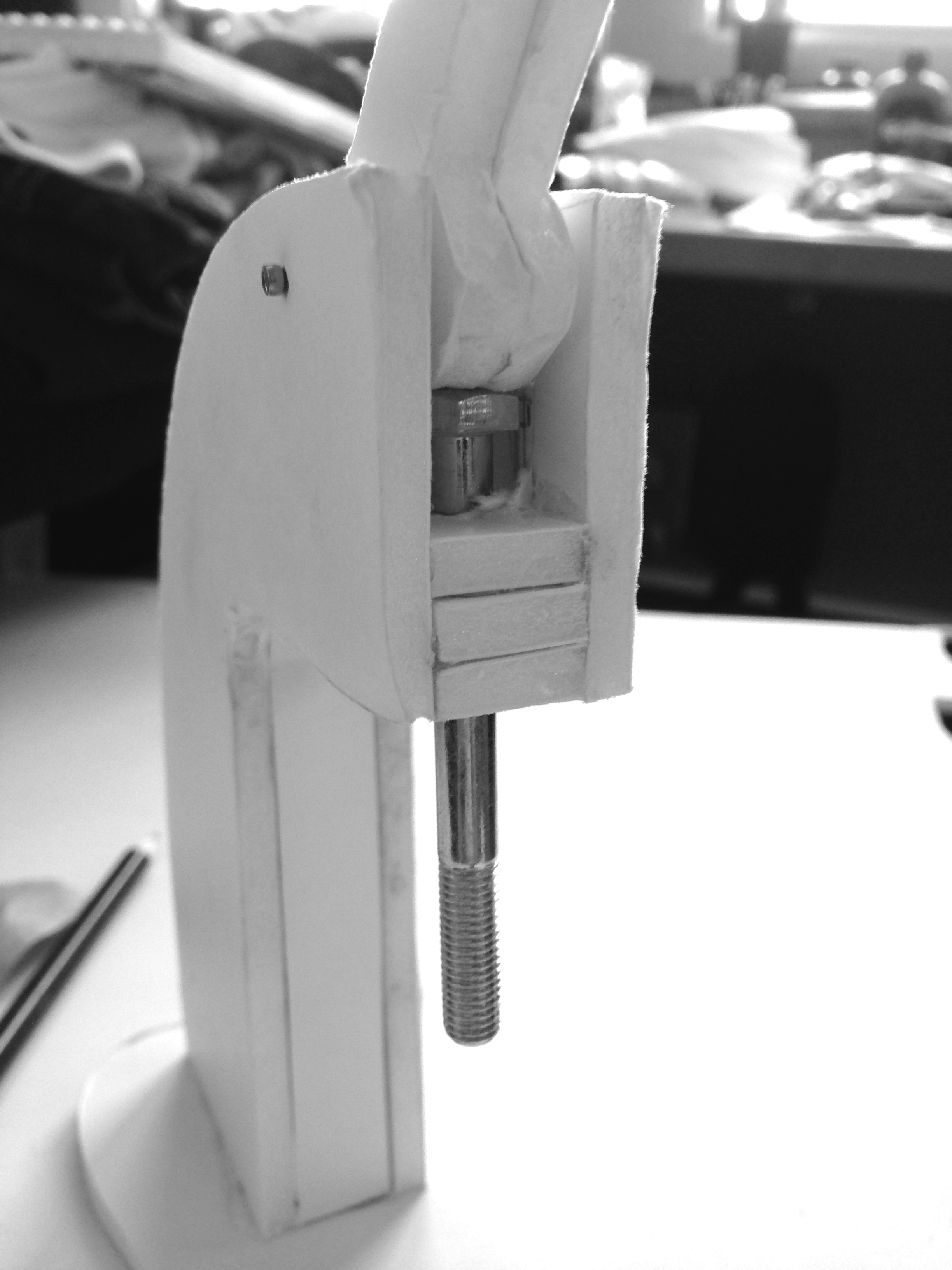

i made the impression press at stanford university in the product realization lab for a design and manufacturing class. the impression is a type of arbor press that uses purchased button-making dies to create personalized buttons.

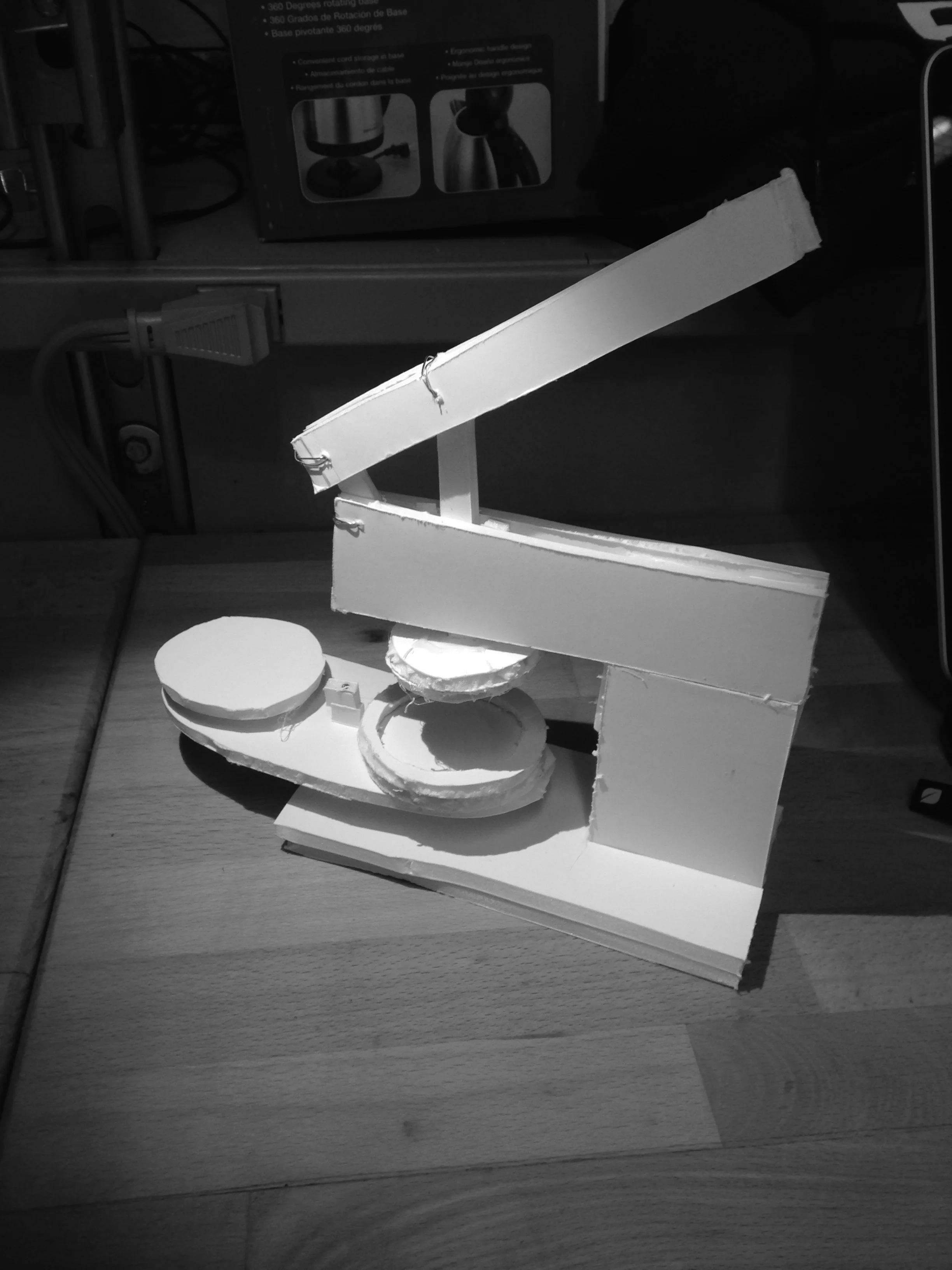

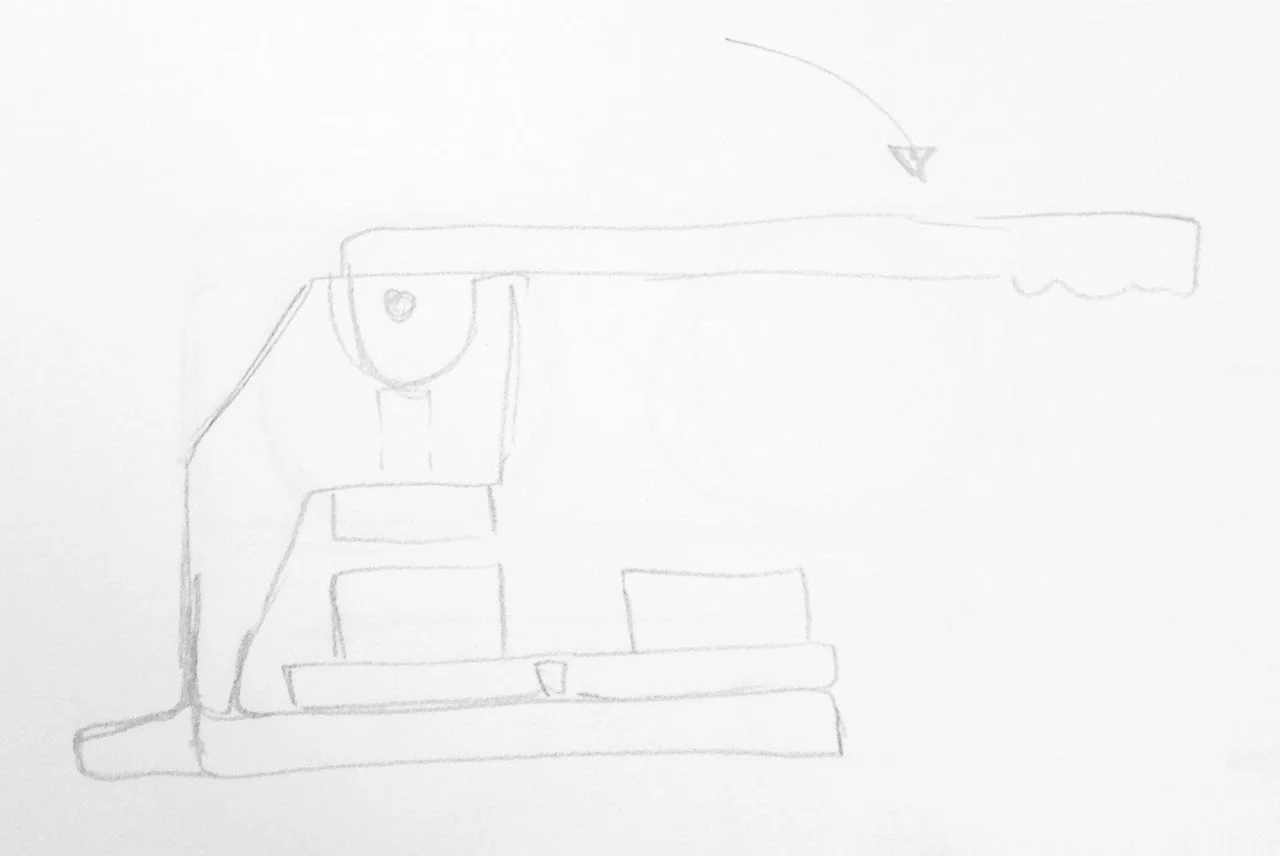

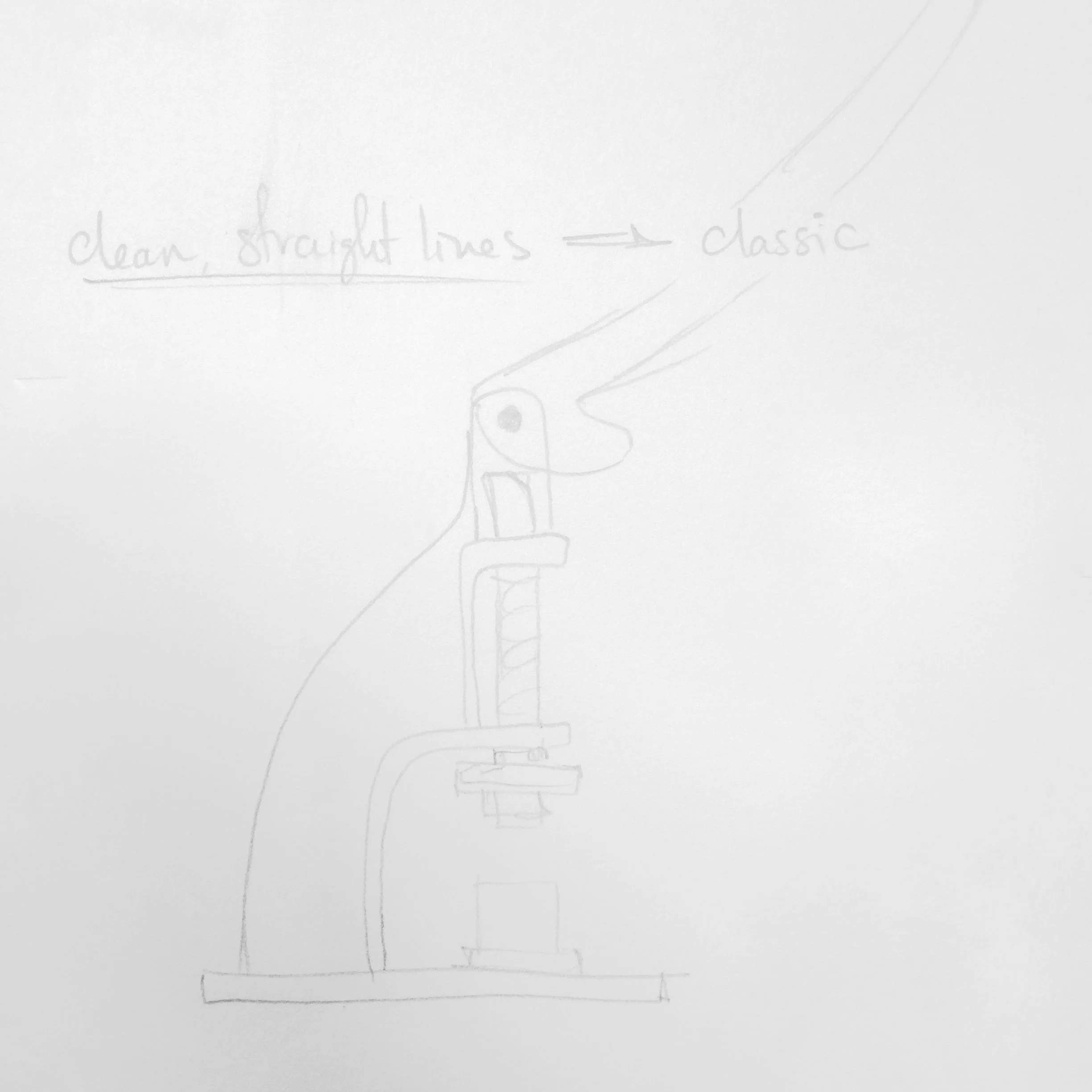

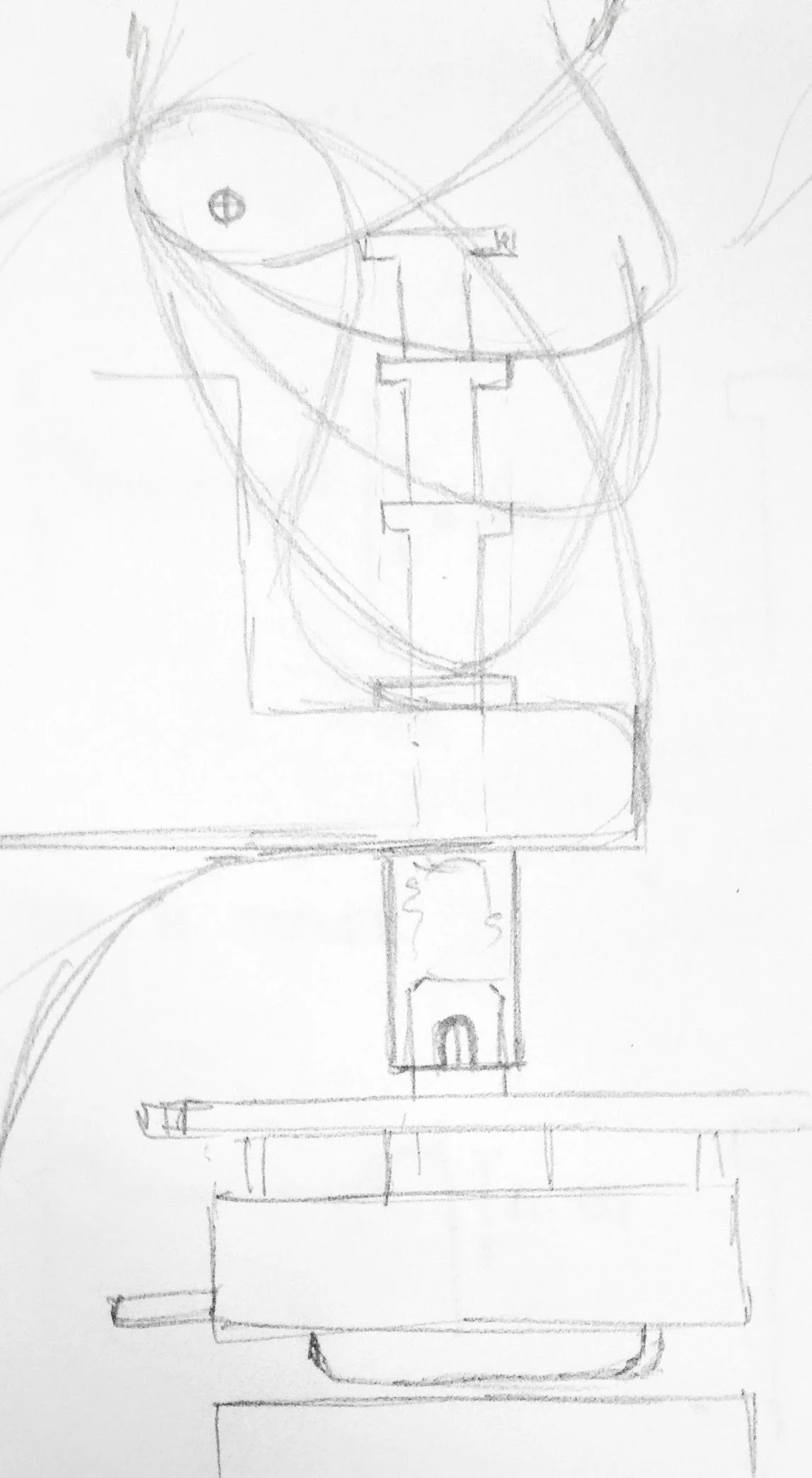

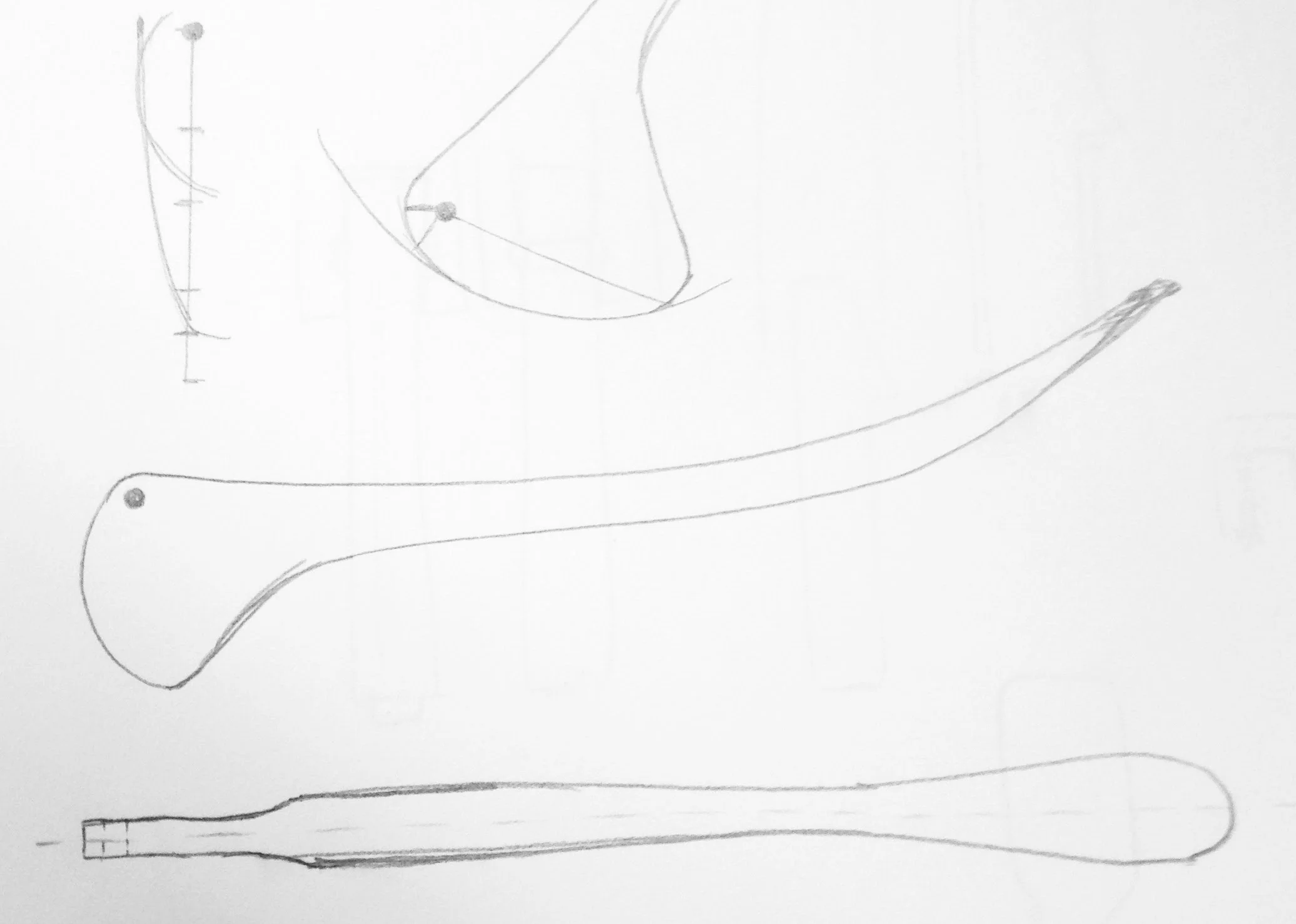

Initial concept sketches and prototypes

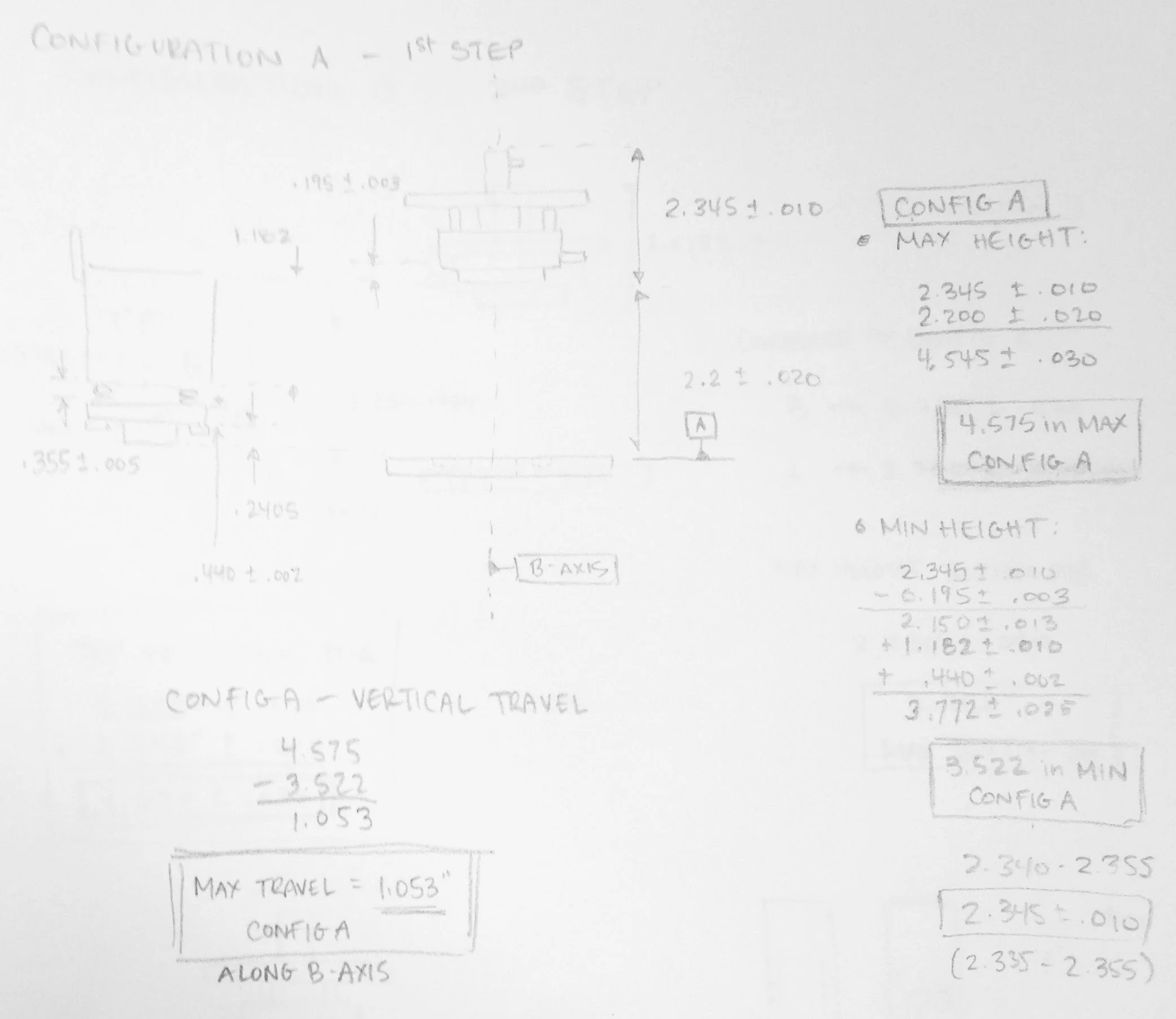

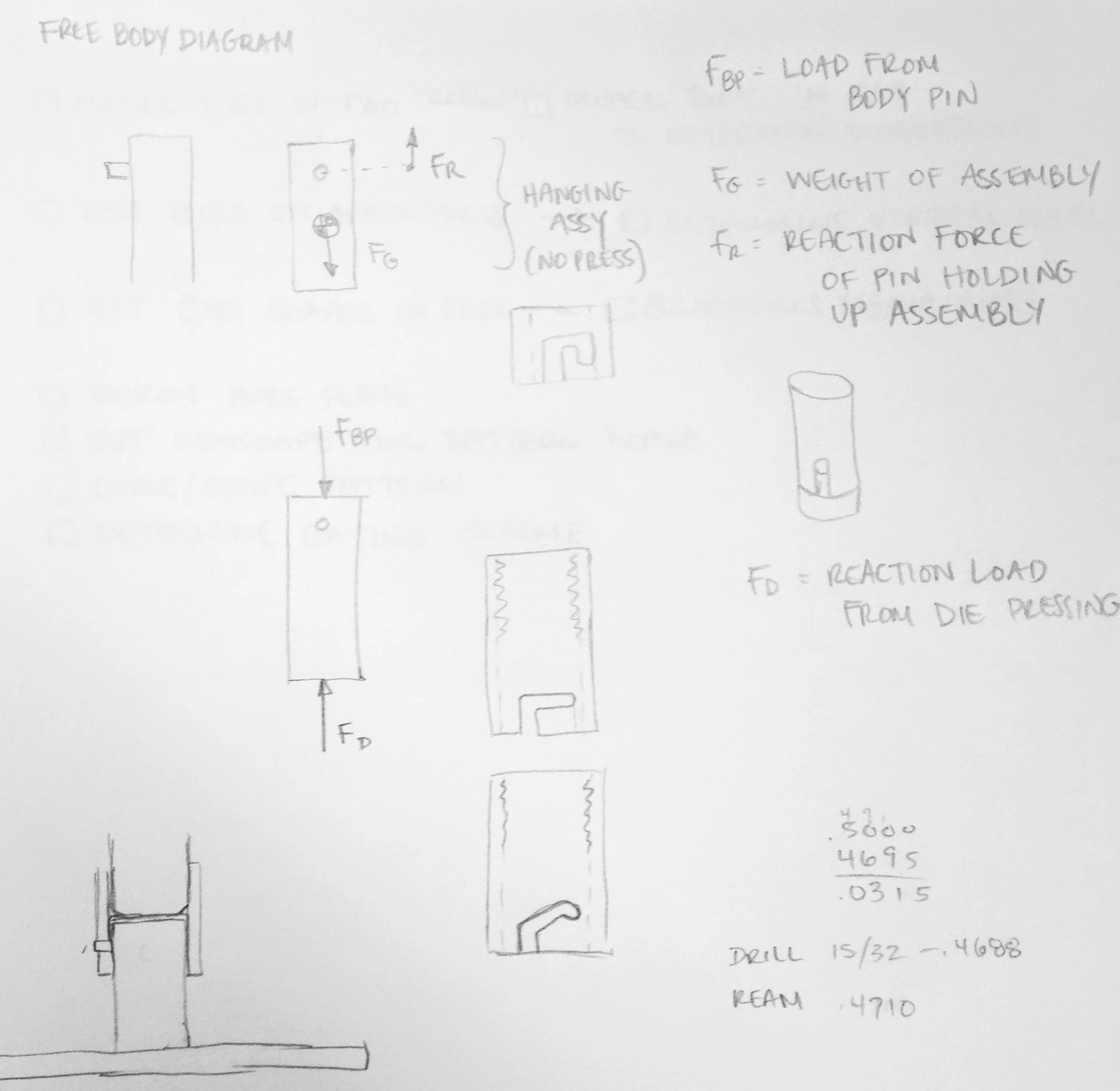

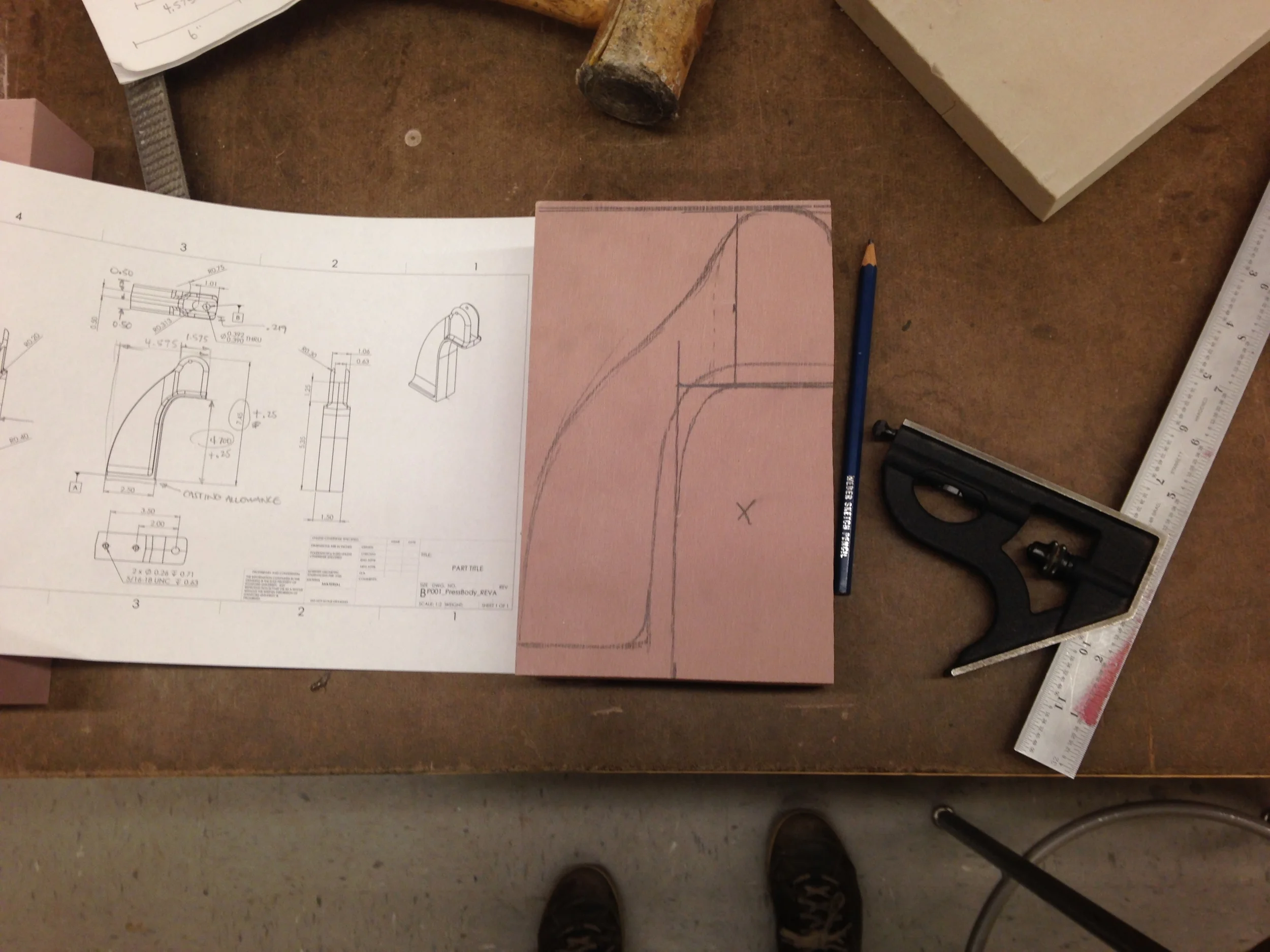

Technical sketches and calculations

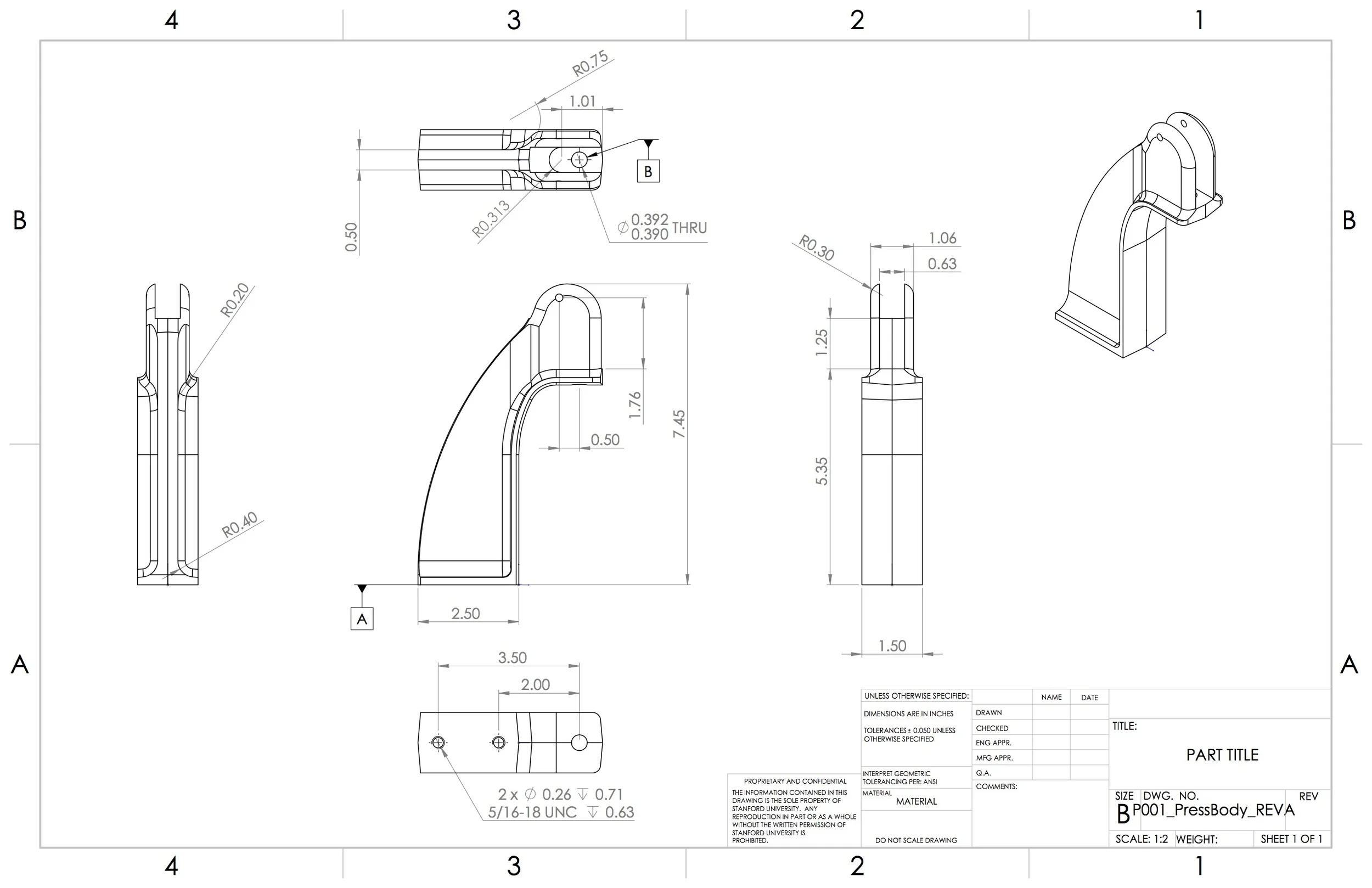

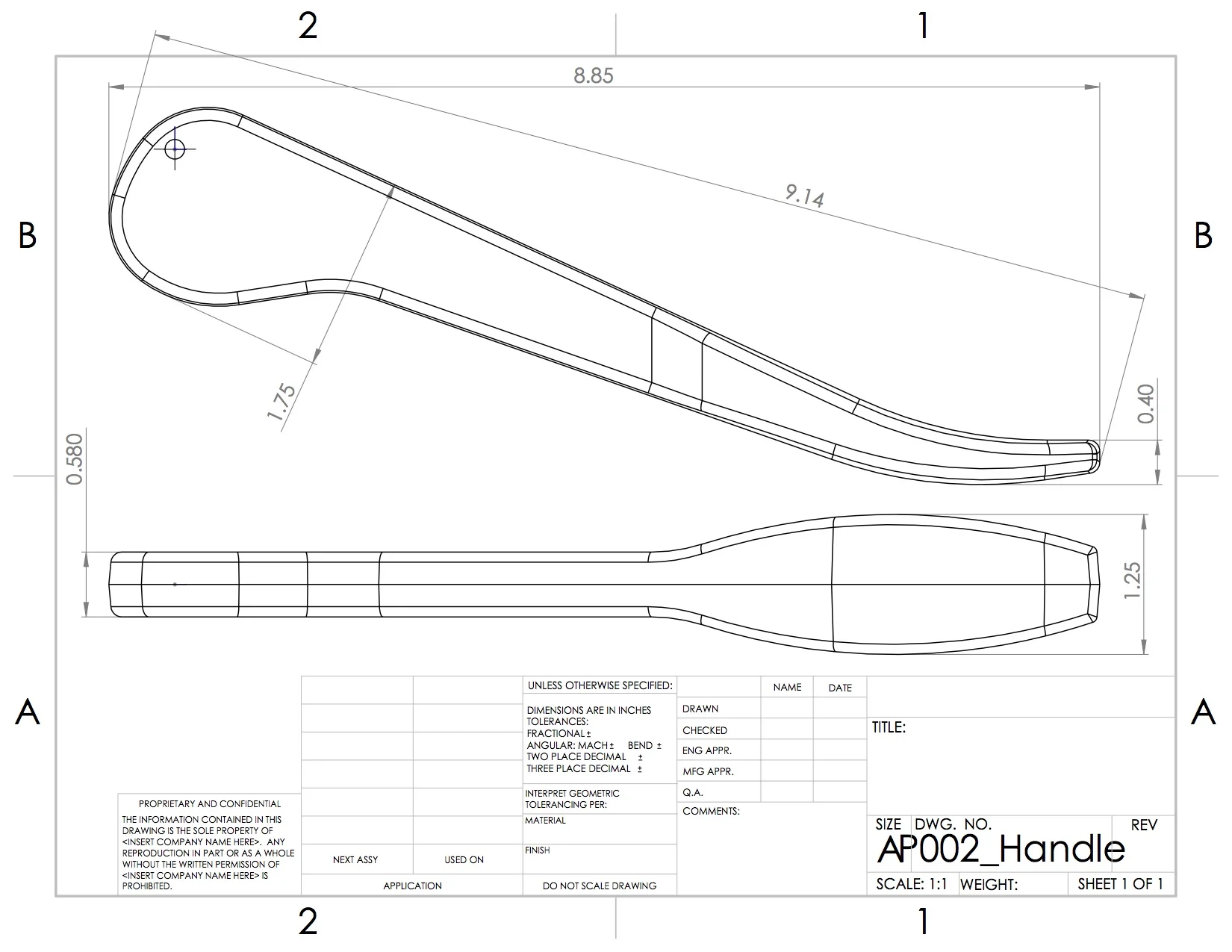

SOLIDWORKS DRAWINGS

manufacturing

woodworking, sand casting, post-machining, finishing

Glamour shots

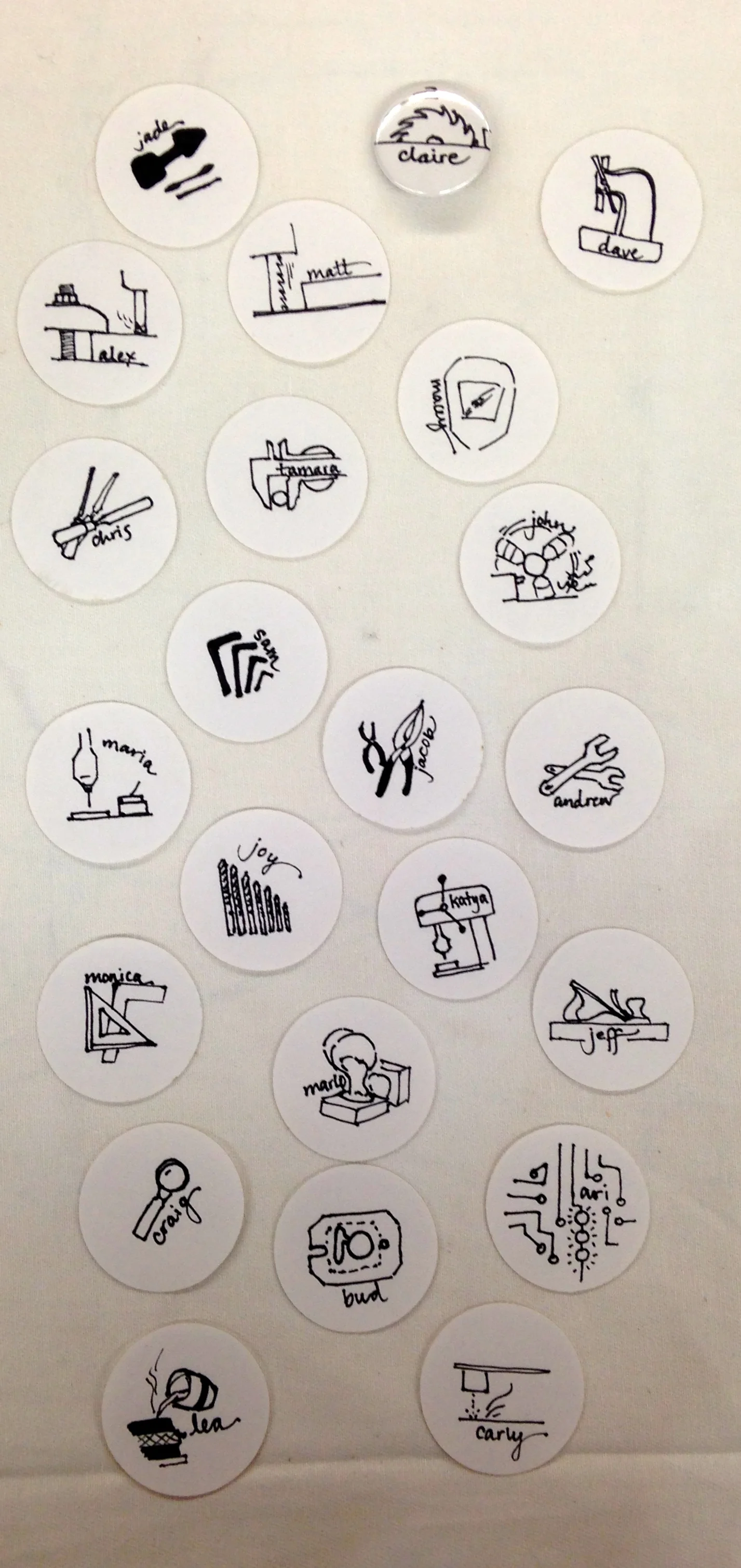

sharing the love

personalized button designs created for classmates and machine shop staff

thanks to the shop TA's and my loftees for advice, encouragement, and inspiration throughout this project!